What products does Markforged offer in the 3D printing industry?

Markforged offers a wide range of 3D printers, including desktop and industrial models. Their products are known for their ability to print with industrial-strength materials like carbon fiber, Kevlar, and fiberglass, making them ideal for producing strong and durable parts for various applications.

Key Highlights

- Revolutionizing the manufacturing industry with strong and durable parts.

- Markforged printers have core features that make them stand out from other 3D printers in terms of precision, versatility, and durability.

- The printing process with Markforged printers is easy and efficient.

- Post-processing techniques such as cleaning and finishing are simple for optimizing prints.

- Carbon fiber 3D printing finds applications in various industries such as aerospace, defense, automotive, and industrial manufacturing.

Introduction

Markforged desktop 3D printers combine the benefits of additive manufacturing and carbon fiber material to produce functional and high-quality parts. Whether you are in the aerospace industry, automotive sector, or industrial manufacturing, Markforged printers can meet your needs.

In this blog, we will explore the world of carbon fiber 3D printing with Markforged. We will delve into the basics of carbon fiber material, understand its benefits in 3D printing, and explore the core features of Markforged printers. We will also discuss the design considerations for printing, the printing process with Markforged, post-processing techniques, common challenges, and advanced techniques in carbon fiber 3D printing. Let’s get started!

Understanding Carbon Fiber in Fused Deposition Modelling (FDM)

Markforged carbon fiber 3D printing combines the power of fused deposition modelling (FDM) technology, also referred to as fused filament fabrication (FFF), with the strength and versatility of carbon fiber, enabling rapid prototyping, complex geometries, and unparalleled customization.

The layer-by-layer approach of FDM 3D printing can create intricate geometries previously impossible or difficult to achieve with traditional methods and internal structures that can enhance the functionality of your printed parts while minimizing material usage.

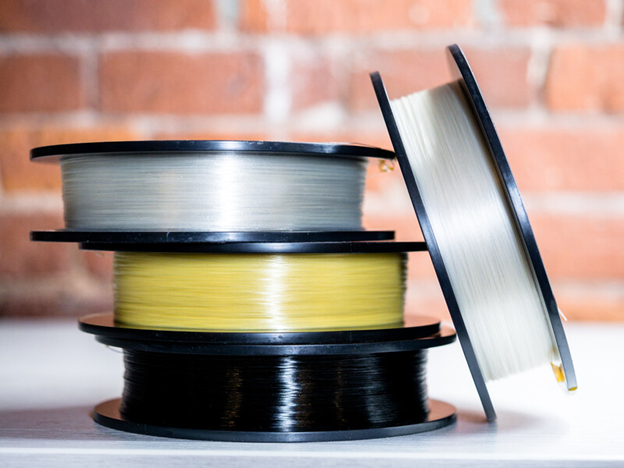

Markforged offers carbon fiber to your 3D prints in 2 ways: a polymer printing filament, Onyx, and as a continuous fiber inlay. Onyx is a micro carbon fiber infused nylon boasting high strength, durability, and resistance to chemicals. We’ll cover continuous inlays a bit later in our exploration.

The Basics of Carbon Fiber Material

Carbon fiber is widely used across industries thanks to its exceptional mechanical properties. It is composed of thin strands of carbon atoms bound together in a matrix material, resulting in a material that is stiff, strong, and lightweight.

One of the key advantages of carbon fiber is its high strength-to-weight ratio. It is stronger than many metals while being significantly lighter. This makes it an ideal material for applications where weight reduction is crucial, such as aerospace or automotive.

Carbon fiber also has excellent fatigue resistance, meaning it can withstand repeated loading and unloading without experiencing significant degradation in performance. This property makes it suitable for applications that involve cyclic loading, such as structural components in aircraft or high-performance sports equipment.

In addition to its mechanical properties, this material is highly resistant to corrosion, which makes it suitable for use in harsh environments or applications where exposure to chemicals is a concern.

From Prototypes to End-Use Parts: Benefits of Using Carbon Fiber in 3D Printing

Carbon fiber is an advanced material that offers exceptional strength, lightweight properties, fatigue and corrosion resistance. These properties make it an excellent choice for applications in industries that require high performance.

The printing process is more efficient compared to traditional manufacturing methods. You can create functional parts directly from digital files, eliminating the need for costly molds or tooling. This not only saves time but also significantly reduces your cost of production.

Additionally, traditional manufacturing methods often result in significant material waste, due to the subtractive nature of the processes. 3D printing adds material only where you need it, minimizing waste and making it a more sustainable manufacturing solution.

Overall, using carbon fiber in 3D printing allows you to create functional parts with more complex designs at a lower cost and with less material waste.

Introduction to Markforged Desktop 3D Printers

Markforged desktop printers are known for their precision, versatility, and durability. They are designed to deliver consistent and accurate prints, ensuring the highest level of quality. Whether you need to create functional prototypes or end-use parts, Markforged printers have got you covered.

Core Features of Markforged Printers

- Precision: Markforged printers are designed to deliver high precision and accuracy, ensuring that every print meets the desired specifications.

- Desktop Size: Markforged desktop printers are compact and convenient for small-scale manufacturing or prototyping operations where space is a constraint.

- Versatility: Markforged printers offer versatility in range of compatible materials. From nylon to patented continuous fiber reinforcement, these printers can handle a wide variety of materials, allowing for greater flexibility in design and application.

- Durability: Markforged printers are built to withstand the demands of industrial use. They are durable and reliable, ensuring consistent performance even in high-volume production environments.

Comparing Markforged with Other 3D Printers

- Deposition Technology: Markforged printers use a precise deposition technology that allows for the controlled placement of material, resulting in high-quality prints with excellent dimensional accuracy and surface finish.

- Repeatability: Markforged printers are known for their repeatability, meaning that they can consistently reproduce the same results with each print. This is important for achieving consistent part quality and performance.

- Range of Materials: Markforged printers offer a wide range of materials to choose from, including carbon fiber, nylon, and other polymers. This allows for greater flexibility in design and application, catering to a variety of industry needs.

- Agility: Markforged printers are equipped with Eiger software, which provides a user-friendly interface and advanced features for optimizing prints. The software allows for easy file preparation, design optimization, and print management, enhancing the overall printing experience.

Overall, Markforged printers stand out from other 3D printers in terms of their deposition technology, repeatability, range of materials, and software agility. These factors make them a preferred choice for high-quality prints and versatile printing capabilities.

Preparing Your Design for Printing

When preparing your design for printing, consider the intricacies of additive manufacturing and the unique properties of carbon fiber. Take into account factors like dimensional stability, precise geometries, and the strength required for functional parts.

Take advantage of the software tools available in Eiger to optimize your design for the printing process, ensuring that your final product meets the desired mechanical properties.

Design Considerations for Additive Manufacturing

When designing for carbon fiber 3D printing, consider structural requirements, layer orientation, and part orientation to optimize strength. Utilize lattice structures for lightweight yet robust designs and ensure proper support structures for complex geometries. Factor in material properties like dimensional stability and mechanical strength for functional parts. Prioritize design for additive manufacturing to leverage the benefits of carbon fiber, such as durability and agility in production.

Software Tools for Optimizing 3D Designs

Eiger by Markforged offers features that optimize designs for additive manufacturing. Tweak parameters for print quality, material properties, and structural integrity. By simulating the printing process virtually, you can ensure that your designs will translate perfectly into physical objects.

Leveraging such software streamlines the manufacturing process, leading to efficient production of durable and precise parts.

Step-by-Step Guide to Your First Carbon Fiber Print

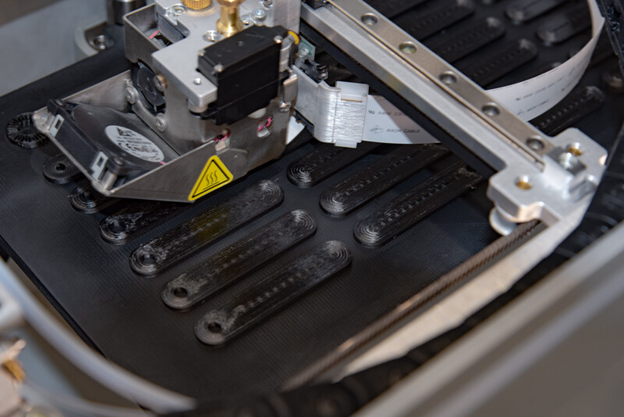

Let’s take a look at the printing process. Step one is always to ensure your Markforged printer is calibrated and that enough of the right filament is loaded.

Next, open Eiger and import your design. Select the material that best meets your application and adjust print settings to your liking. Generate toolpaths and preview the print.

If all looks good, send the file to the printer directly from Eiger.

Monitor your print’s progress either at the printer or online through Eiger. Once complete, carefully remove the print from the print bed.

Post-process by removing any support structures and gently sanding away any material left behind for a flawless surface finish.

Finally, celebrate your successful debut into carbon fiber 3D printing!

Tips for Ensuring Print Quality and Strength

To guarantee optimal print quality and strength when using your Markforged for carbon fiber 3D printing, consider these essential tips:

- Ensure proper bed leveling and nozzle calibration for precise prints.

- Optimize print settings such as layer height and infill density to balance strength and print time.

- Monitor the printing process regularly to catch any issues early, and post-cure parts when necessary for enhanced strength and durability.

Post-Processing of Carbon Fiber Prints

Cleaning and finishing carbon fiber prints is a breeze. Finishing touches like sanding or polishing can further refine the surface quality. However, to enhance the final aesthetics and durability, use gentle cleaning methods to avoid damaging any intricate details.

Cleaning and Finishing Techniques

When it comes to cleaning and finishing techniques for your carbon fiber prints, precision is key. Gently remove any support structures using tools like pliers or tweezers. To smooth out rough edges, use fine grit sandpaper for a flawless finish.

Post-Processing Safety Tips

Remember to prioritize safety when post-processing your prints. Wear appropriate protective gear like gloves and eyewear to avoid contact with any residual fibers or dust. Always follow the manufacturer’s guidelines for handling any finishing agents or solvents to prevent any accidents or health risks.

Remember, safety first!

Common Challenges and Solutions

Issues like delamination, warping, or filament breakage can occur. To combat this, ensure proper bed adhesion and environmental control. Fine-tuning print settings for layer adhesion and infill density can enhance strength. Also, inconsistent fiber alignment may lead to weaker parts; adjusting parameters in the slicer software can resolve this.

Regular maintenance, like calibrating and cleaning your printer, also plays a key role in mitigating challenges; Troubleshooting promptly ensures smooth printing processes and a long life for your printer.

Troubleshooting Common Issues

Regular maintenance and adjustment can resolve many printing problems, ensuring smooth and successful prints.

- One common issue in FDM 3D printing is delamination, where layers separate. To address this, ensure the print bed is leveled correctly and your printer environment isn’t too humid.

- Warping can occur due to inadequate bed adhesion or cooling, so adjust printer settings or environmental factors like temperature and humidity to prevent this.

- Issues with layer adhesion might stem from incorrect print temperatures or inadequate filament flow. Check these settings and calibrate them for optimal results.

Advanced Techniques in 3D Printing

Advanced techniques elevate the capabilities of the material, offering unparalleled versatility and strength for various industrial applications. To enhance the strength of your carbon fiber 3D prints, try incorporating continuous fiber inlays.

Incorporating Continuous Fiber for Added Strength

This process involves strategically placing continuous strengthening fibers within your print to reinforce specific areas, providing added durability and structural integrity. By utilizing this method, you can boost the mechanical properties of your carbon fiber parts, making them ideal for applications requiring high strength and precision. This technique elevates the overall performance of your printed components, making them more resilient to various stresses and strains, contributing to the durability and functionality of your final product.

Applications for Carbon Fiber 3D Printing

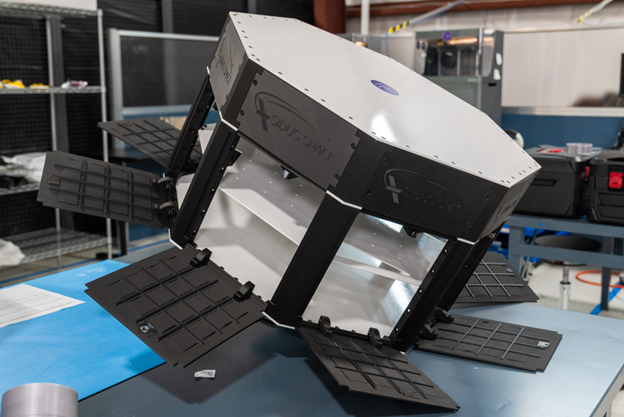

Aerospace and Defense, Automotive and Transportation, and Industrial Manufacturing are prime examples of where carbon fiber 3D printing excels. In Aerospace, the lightweight yet durable nature of the Markforged material enhances fuel efficiency. The Automotive sector benefits from the material’s strength to weight ratio for components like body panels. Industrial Manufacturing leverages carbon fiber’s durability for machinery parts.

These applications showcase the versatility and strength of carbon fiber.

Aerospace and Defense

The lightweight yet sturdy nature of carbon fiber is ideal for creating parts with high mechanical properties and dimensional stability. Markforged’s printers can produce intricate designs with thin walls and complex geometries, ensuring precision and durability in critical components. By utilizing additive manufacturing technology, the production process is agile and cost-effective, making it a preferred choice for rapid prototyping and spare parts manufacturing in the aerospace and defense sectors, ultimately speeding up the product development process.

Automotive and Transportation

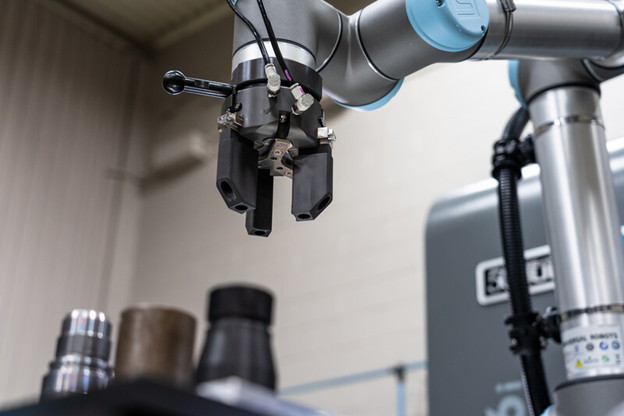

3D printing with carbon fiber has found remarkable utility in the automotive and transportation sectors. Markforged printers offer precision and agility in producing functional parts with superior mechanical properties. By incorporating continuous fiber, these printers create durable components ideal for applications requiring strength and lightweight characteristics. From rapid prototyping to spare parts production, Markforged drives innovation in automotive manufacturing.

Industrial 3D Printing & Manufacturing

With its agility and versatility, Markforged brings additive manufacturing to the forefront of creating durable and functional parts for industrial applications. The precision and repeatability of Markforged printers ensure that complex designs with thin walls can be printed with utmost dimensional stability, meeting the stringent requirements of the manufacturing sector. Additionally, Markforged offers the unique capability of printing with composites through fused filament fabrication (FFF) for even stronger and more lightweight parts to be produced in a fraction of the lead time compared to traditional methods.

Conclusion

Mastering carbon fiber 3D printing opens up a world of design possibilities. Browse through our resource center to learn more.

Are you ready to bring the strength of carbon fiber to your 3D prints? Reach out to our dedicated 3D printing Xperts today to learn how Markforged can elevate your 3D printing game to the next level!