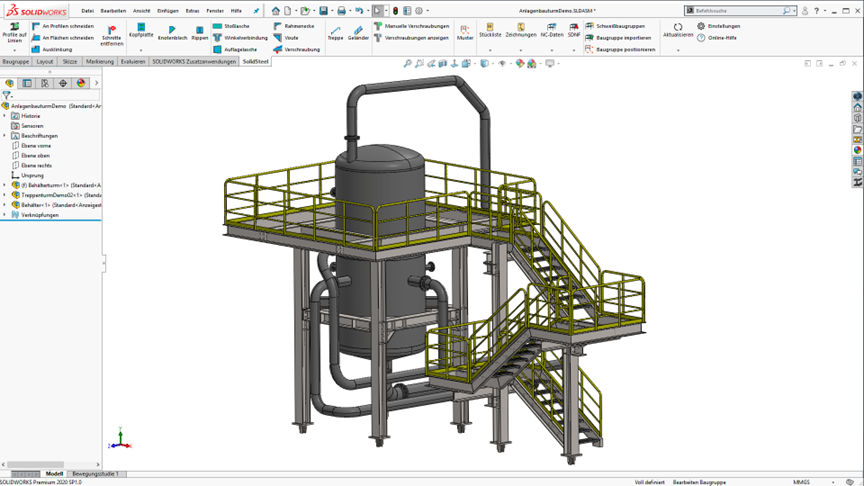

The structural steel industry is undergoing a rapid transformation, driven by software innovations that simplify the work of engineers, designers, and manufacturers. One of the key drivers of this transformation is the automation of fabrication through standardized file formats, chief among them the DSTV format (Deutscher Stahlbau-Verband), which has become a standard in the industry.

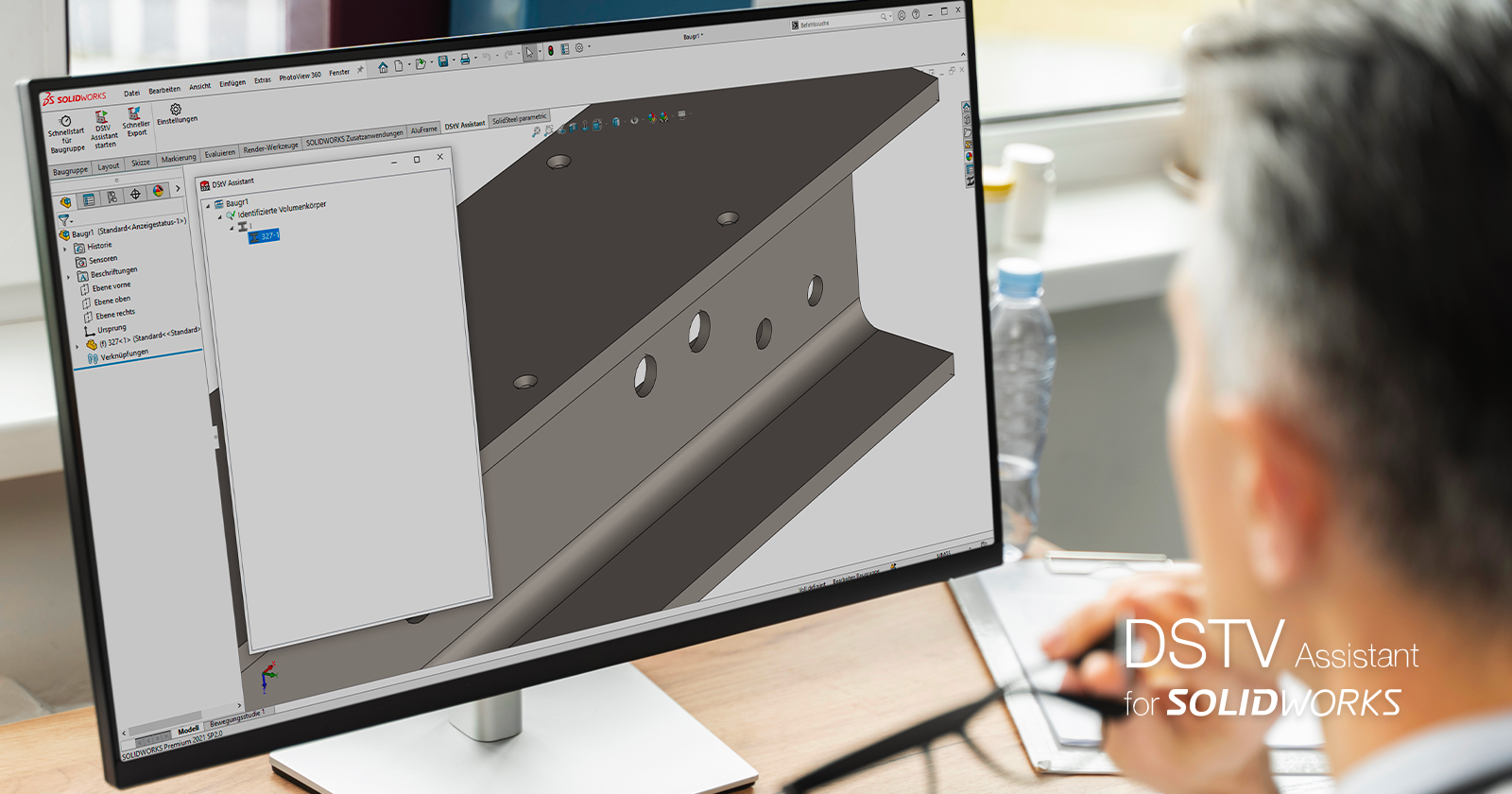

The DSTV module of SolidSteel, integrated within the SOLIDWORKS environment, enables the automatic generation of DSTV files directly from 3D models. This process streamlines the fabrication of steel components, improves precision, reduces human error, and shortens production timelines. Provided by Solidxperts with personalized training and support, this solution becomes a strategic asset for any company involved in designing and fabricating steel structures.

In this blog post, we’ll explore the added value of the SolidSteel DSTV module, its seamless integration with SOLIDWORKS and other platforms, and the training and consulting services offered by Solidxperts, your trusted partner in digital transformation.

1. What Is the DSTV Format and Why Is It Essential?

The DSTV format (.nc) was developed by the German Steel Construction Association to enable machine tools, particularly CNC machines, to directly read fabrication data for steel parts. It is a text-based file containing all machining instructions: drilling, cutting, beveling, notching, etc.

Why is DSTV crucial in modern steel fabrication?

-

Standardization: It’s globally recognized and compatible with most CNC equipment.

-

Precision: Eliminates manual conversion or transcription errors.

-

Time Savings: Generates production-ready files directly from 3D models.

-

Traceability: Facilitates better process management and quality control.

This is where SolidSteel’s DSTV module comes in, unlocking the full power of the DSTV format within the world’s most widely used 3D CAD environment, SOLIDWORKS.

2. Added Value of the SolidSteel DSTV Module

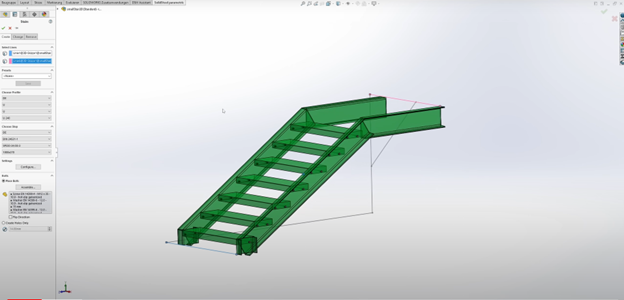

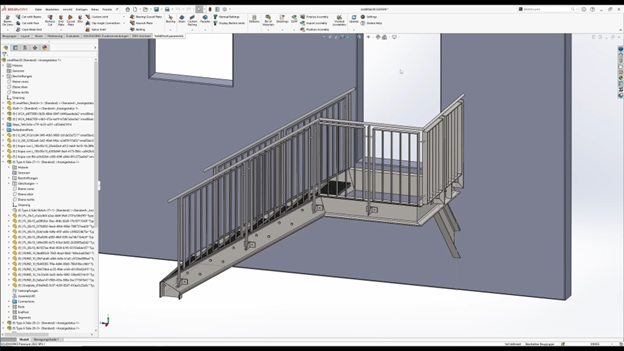

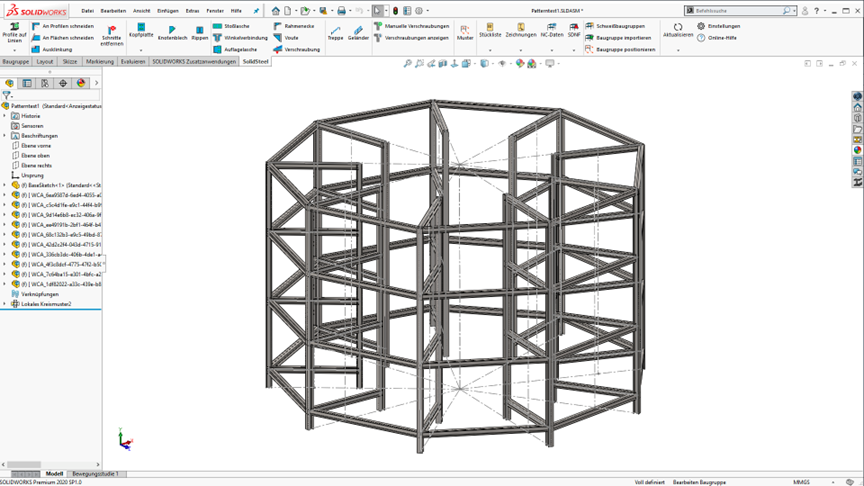

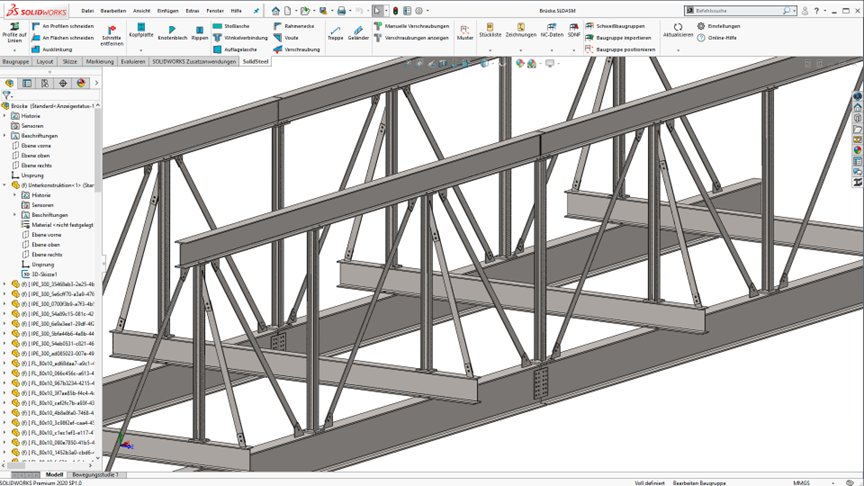

SolidSteel is a powerful parametric modeling solution for steel structures, fully embedded in SOLIDWORKS. Its DSTV module offers a seamless bridge from design to manufacturing.

Key benefits include:

a. Automated Fabrication Workflow

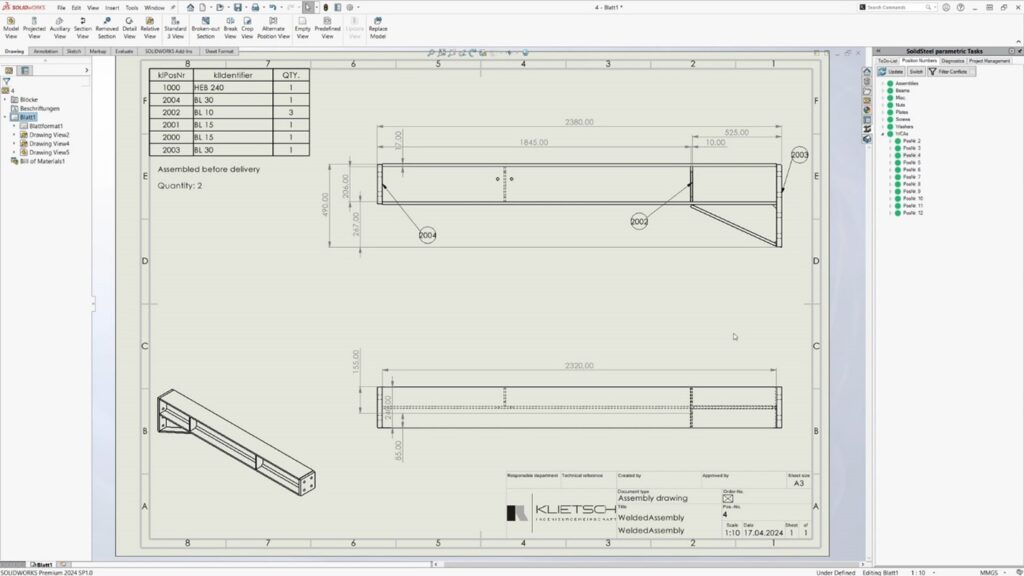

The module automatically generates (.nc) files for every profiled part, complete with cutting, drilling, and marking data. Eliminating the need for manual exports or third-party converters.

b. Increased Accuracy

By using the 3D model as the single source of truth for production data, the risk of errors is greatly minimized. Every detail is derived from the master model, ensuring perfect alignment between design and production.

c. Time and Cost Efficiency

Reducing manual tasks and interpretation errors saves valuable time per project, minimizes on-site modifications, and cuts down on costly rework.

d. Compatibility with Various CNC Machines

The DSTV files generated by SolidSteel work with nearly all CNC machines in steel fabrication, including Peddinghaus, Ficep, Voortman, Kaltenbach, and others.

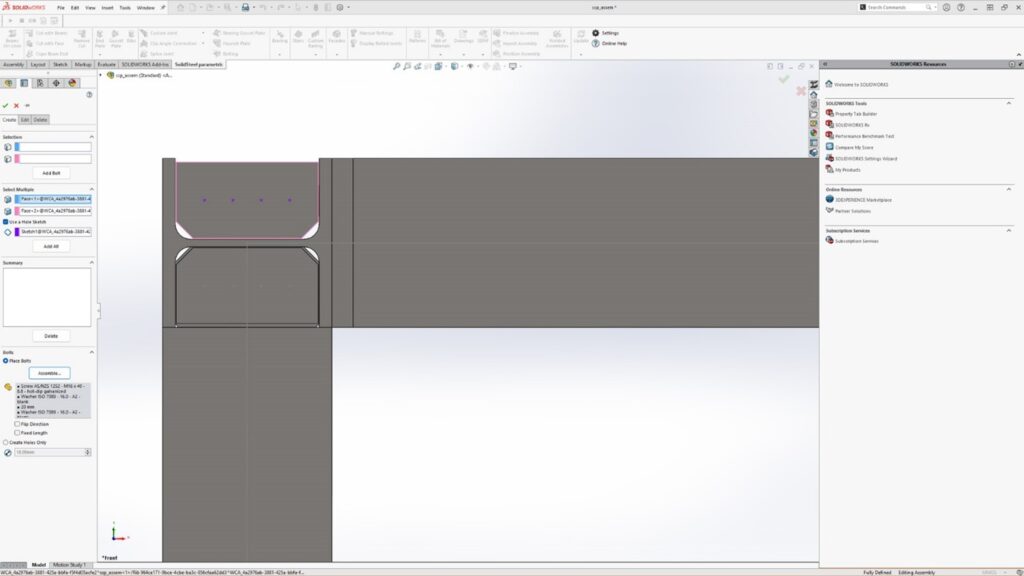

e. Smooth Workflow Integration

Users can generate DSTV files without ever leaving the SOLIDWORKS interface, making it easy for designers unfamiliar with CNC programming to contribute to production seamlessly.

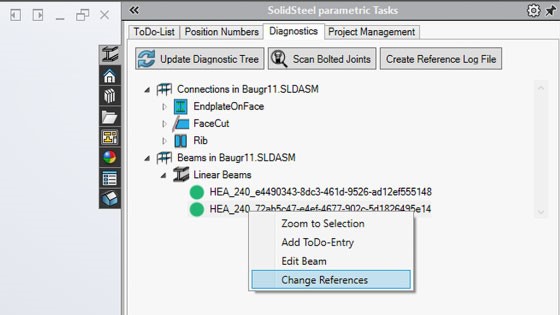

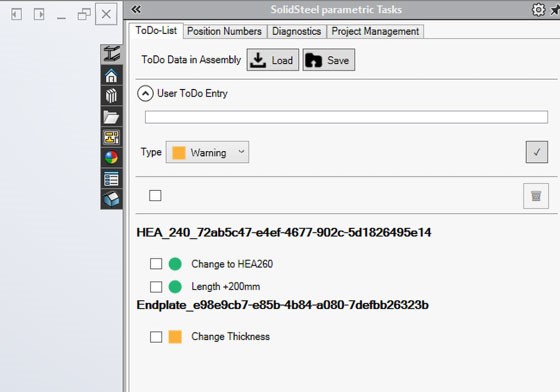

3. Integration with SolidSteel DSVT Module and Other Software

The SolidSteel DSTV module operates natively within SOLIDWORKS, offering a smooth experience for engineers and designers. Here’s how it integrates and connects with other tools:

a. SOLIDWORKS: A Robust Foundation

SolidSteel is fully embedded into SOLIDWORKS, leveraging its familiar interface, parametric modeling tools, and design engine. Key features include:

-

A consistent and intuitive user interface

-

Direct use of dimensioning and drawing tools

-

Support for international profile standards (DIN, ASTM, etc.)

-

Full compatibility with assemblies, configurations, and BOMs

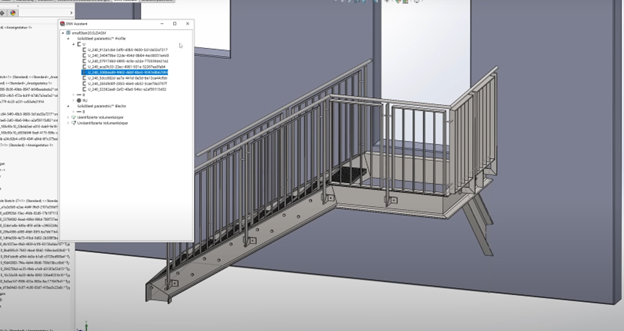

b. Direct DSTV File Generation from SOLIDWORKS

DSTV files can be automatically created for each steel profile directly from the 3D model. Users can adjust export settings, including naming conventions, tolerances, and drilling formats.

c. Interoperability with Other Software

Although optimized for SOLIDWORKS, the exported DSTV files are universal. Companies can integrate them into ERP, MES, simulation, or external CNC programming tools. They also work with BIM platforms, supporting cross-disciplinary collaboration (concrete, electrical, MEP, etc.).

d. Customization and Extensions

The DSTV module can be enhanced with additional tools such as:

-

ERP/MRP Integration: Sync with production planning systems

-

PDM Compatibility: Version control and file management

-

Structural Analysis Add-ons: Connect with tools like RSTAB or Autodesk Robot for material strength calculations

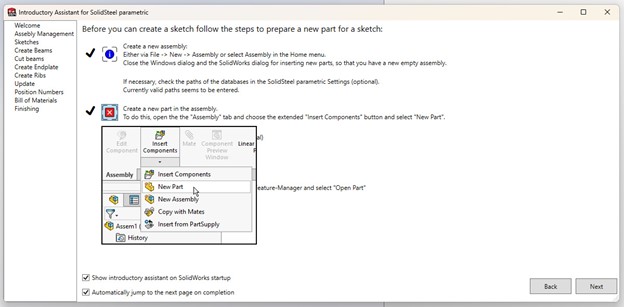

4. Training and Support by Solidxperts

Adopting such a high-performance solution requires tailored training and strategic guidance. This is where Solidxperts stands out.

a. Customized Training Programs

Solidxperts offers training that’s adapted to your industry (structural steel, industrial, infrastructure, etc.) and your team’s level of expertise in SOLIDWORKS. Training covers:

-

Getting started with SolidSteel

-

Using the DSTV module

-

Setting up CNC-specific export parameters

-

Best practices to ensure design-to-fabrication consistency

Training sessions are available on-site, online, or in-person.

b. Dedicated Technical Support

Solidxperts’ team includes certified trainers and experienced application engineers who provide responsive technical support and guidance on advanced features.

c. Webinars and Learning Resources

Beyond traditional training, Solidxperts regularly offers webinars, video tutorials, technical articles, and Q&A sessions to help your team stay current and deepen their expertise.

d. Implementation and Strategic Consulting

Solidxperts also helps companies integrate the DSTV module strategically into their workflow, including:

-

Analyzing current processes

-

Configuring software to meet specific needs

-

Creating customized templates and part libraries

-

Integrating with workshop CNC machines

What Could SolidSteel DSTV Unlock for Your Projects?

The SolidSteel DSTV module is far more than a CNC file generator. It’s a strategic tool that connects digital design with real-world production efficiently and accurately. Integrated into SOLIDWORKS, it empowers engineers to streamline their workflows, reduce errors, and meet modern project demands in steel construction.

With Solidxperts’ expertise and support, companies can quickly deploy this solution, train their teams, and digitally transform their production lines, staying competitive in a rapidly evolving market.

Want to learn more or schedule a live demo? Contact Solidxperts today and discover how the SolidSteel DSTV module can revolutionize the way you design and fabricate steel structures.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: