TL;DR

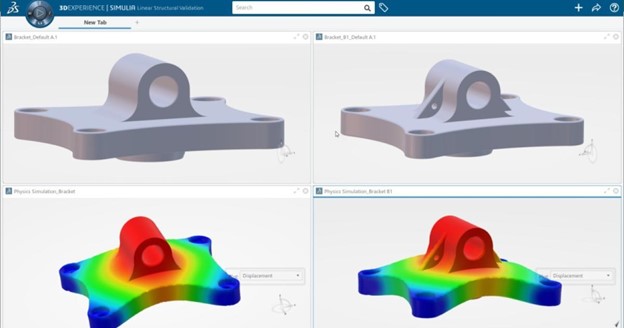

SOLIDWORKS 2025 brings a new era of simulation capabilities, in partnership with the 3DEXPERIENCE platform, redefining how engineers validate designs and optimize workflows. With cutting-edge features like the General Spring Connector, enhanced surface bonding interactions, and performance improvements for large assemblies, this year’s release empowers users to achieve greater accuracy and efficiency in their simulations.

Engineers can now streamline complex setups, precisely analyze plastic warpage, and handle fluid dynamics with ease, all while benefiting from improved usability and faster meshing processes. This blog explores the key simulation upgrades in SOLIDWORKS 2025, offering insights into how these tools transform the engineering experience.

Intro

In the world of engineering and design, simulations are the backbone of validation. They ensure products perform as intended, withstand real-world conditions, and remain cost-effective. With the release of SOLIDWORKS 2025, simulation capabilities have reached new levels, offering more precise results, streamlined workflows, and advanced usability improvements that empower engineers to work smarter, not harder.

This blog explores the transformative enhancements in SOLIDWORKS 2025 Simulation, breaking down the key features and their practical applications. Whether you’re tackling large assemblies, complex geometries, or detailed fluid dynamics, these updates provide a powerful suite of tools to support every stage of the design process.

General Spring Connector: Simplified and Accurate Simulations

Simulation setups can be complex, but SOLIDWORKS 2025 introduces the General Spring Connector, which makes it easier to simulate spring interactions with more customization options than ever before.

What’s New

- Custom Spring Properties: Define axial-only, isotropic, or orthotropic spring behaviors to suit your design needs.

- Enhanced Compliance: Add custom compliance for greater control over how the spring behaves in different scenarios.

Why It Matters

Springs play a critical role in many mechanical systems, from suspension components to load-bearing structures. The General Spring Connector allows for more realistic simulations of spring behavior without requiring physical prototypes. For instance, engineers designing suspension systems can now test how springs react to various loads and stresses while accounting for unique material properties or configurations. By enabling greater precision in spring simulations, this feature saves time during setup and ensures your models reflect real-world performance.

Enhanced Pin Connector: Precision at Every Step

Connections between components are foundational to any assembly simulation. The improved Pin Connector in SOLIDWORKS 2025 refines this process, delivering better accuracy and performance for complex assemblies.

What’s New

- Distributed Connection Type Improvements: Experience improved accuracy when using distributed connections.

- Better Performance: Enjoy faster and more reliable simulations of pin-based connections, especially in large assemblies.

Why It Matters

Pin connectors are crucial for analyzing components like hinges, joints, or pivots. With the upgraded Pin Connector, engineers can confidently simulate these critical interactions while maintaining speed and accuracy. For example, in aerospace applications, where safety hinges on the integrity of pinned connections, these improvements provide deeper insights into load distribution and stress points.

Improved Handling of Large Models

Large assemblies often involve hundreds or thousands of components, making simulation setups a daunting task. SOLIDWORKS 2025 introduces tools to simplify and streamline these workflows.

What’s New

- Exclude Non-Relevant Components: Quickly remove non-essential parts or bodies from simulations to declutter your workspace.

- Focus on Selected Bodies: A new user interface option lets you isolate selected components for faster boundary condition setups.

Why It Matters

These enhancements allow you to focus on the components that matter most, reducing setup time and distractions. Imagine working on a complex machine assembly with hundreds of parts—these tools ensure you can isolate the gearbox, for example, without manually hiding or excluding other components. This targeted focus improves efficiency and helps maintain clarity throughout the simulation process.

Advanced Surface Interactions for Better Results

Accurate bonding between surfaces is essential for reliable simulations. SOLIDWORKS 2025 enhances both Node-to-Surface and Surface-to-Surface Bonded Interactions to improve accuracy and usability.

What’s New

- Offset Bonded Interactions: Eliminate gaps between surfaces in mid-surface mesh studies for better results.

- Improved Bonding for Complex Surfaces: Achieve more precise bonding on cylindrical, spherical, and conical surfaces for linear studies.

Why It Matters

Surface interactions often determine the success of a simulation. By improving bonded interaction accuracy, these upgrades ensure your models perform more like their real-world counterparts. Whether analyzing pressure vessels, complex geometries, or fatigue scenarios, you’ll experience faster, more reliable results with minimal setup adjustments.

SOLIDWORKS Plastics: Analyze Warpage with Precision

Warpage in plastic parts is a common issue that can lead to costly rework or manufacturing delays. SOLIDWORKS 2025 introduces advanced tools to pinpoint and address the causes of warpage.

What’s New

- Break Down Warpage Causes: Analyze warpage by its sources, including unbalanced cooling, material orientation, and non-uniform shrinkage.

Why It Matters

This feature gives engineers greater control over the injection molding process, enabling faster corrections and better part quality. For example, if unbalanced cooling is the primary cause of warpage in a plastic enclosure, engineers can focus their efforts on redesigning the cooling channels, rather than adjusting other unrelated parameters.

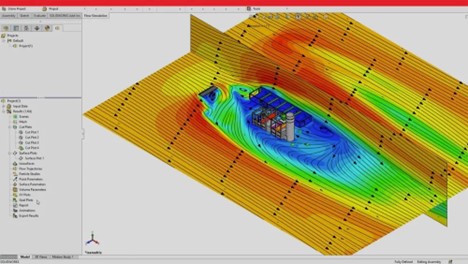

SOLIDWORKS Flow Simulation: Speed and Accuracy Combined

Simulating fluid dynamics just became faster and more efficient. SOLIDWORKS 2025 includes performance and accuracy improvements for handling complex geometries and fluid flow challenges.

What’s New

- Meshing for Faceted Geometries: Accelerate meshing for imported STL files and tessellated models.

- Sink Mark Solver Upgrade: A new solver delivers higher accuracy for predicting sink marks in plastic parts.

Why It Matters

Flow simulations are vital for evaluating designs with fluid flow, such as cooling systems, HVAC components, or aerodynamics. These updates make it easier to handle complex shapes, reducing meshing time while maintaining accuracy. Engineers designing heat exchangers, for instance, can now spend more time optimizing performance rather than troubleshooting simulation issues.

Mesh Performance Upgrades

Meshing is a critical step in any simulation, and SOLIDWORKS 2025 improves performance for assemblies with repeated parts, such as bolts or gears.

What’s New

- Faster Meshing for Repeated Parts: Improved handling of curved surfaces in large assemblies with many identical components.

Why It Matters

Large assemblies often include numerous repeating elements that can slow down meshing. This enhancement drastically cuts meshing time, allowing engineers to focus on analysis rather than setup. For example, an automotive engineer simulating an engine block with hundreds of bolts will see significant time savings during the meshing process.

Why Choose SOLIDWORKS 2025 for Simulation?

SOLIDWORKS 2025 Simulation offers a robust suite of upgrades that cater to engineers working on diverse projects.

Key Features

- Time-Saving Features: From faster meshing to improved handling of large models, every feature is designed to streamline workflows.

- Enhanced Accuracy: Precise bonding interactions, upgraded solvers, and advanced connectors ensure simulations reflect real-world conditions.

- Improved Usability: A cleaner interface and targeted tools reduce complexity, allowing users to focus on engineering, not troubleshooting.

The Solidxperts Advantage

At Solidxperts, we’re committed to helping you unlock the full potential of SOLIDWORKS 2025 Simulation. Our expert team is ready to support you with training, implementation, and ongoing assistance, ensuring your workflows are optimized for success.