Repair Resolution –

You might be an engineer – if, you fix broken fitness equipment with CAD and 3D printing. This case study shows just how that was done. It starts with a budget water rower exercise machine that had arm failures in the resistance paddle which spins inside the water tank. The machine had been purchased early in the year and the paddle arms failed by December.

Note that the arms of the original paddle broke off where the plastic transitions from a thinner beam profile to the larger hub. Of course, it could have been predicted by using SOLIDWORKS Flow, Plastics, or Simulation software, but that discussion will be saved for another article.

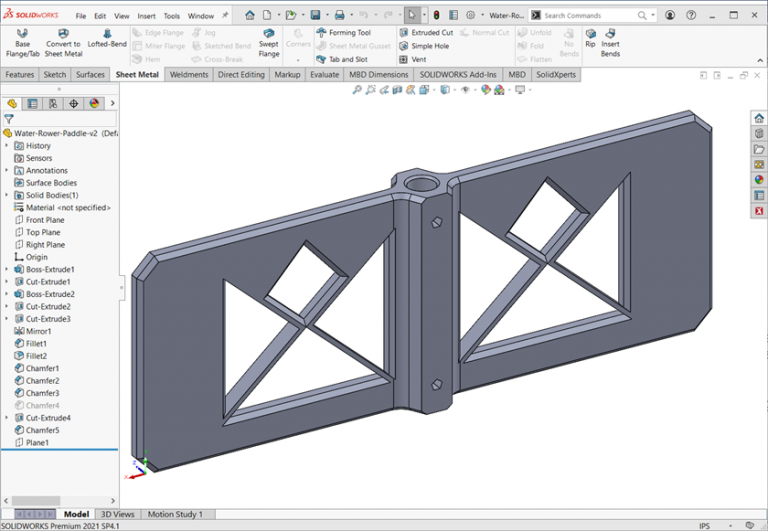

For the moment we will focus on designing and producing a 3D printed replacement paddle that is more similar to the design used in expensive health club water rower machines.

The commercial grade water rower has single mixing paddle design that extends across the diameter of the tank. There are openings between the shaft hub and the scoop ends, but the paddle has solid plastic arms at the top and bottom of the water tank. The budget rower was connected only at the bottom of the water tank leading to increasing offset dynamic loads as athlete exertion increases.

Although the original design paddle diameter of 18 inches is larger than many 3D printer print volume dimensions, it was possible to get 16 inches diagonally across the build plate. Adjusting the width of the working portion of the paddle and having the solid section on top allows the surface area displacing the water to be similar between the 3D printed design and the injection molded paddle.

By using a pattern of triangle and diamond shapes for the open section, the replacement paddle can be printed without support.Chamfers are used for edge breaks around the edges and openings for better flow characteristics while still being easy to print.

The original paddle had a pressed and brazed connection between the paddle and rower shaft, and this has been replaced with a pentagon shaped hole to allow for screw fastening to the shaft.

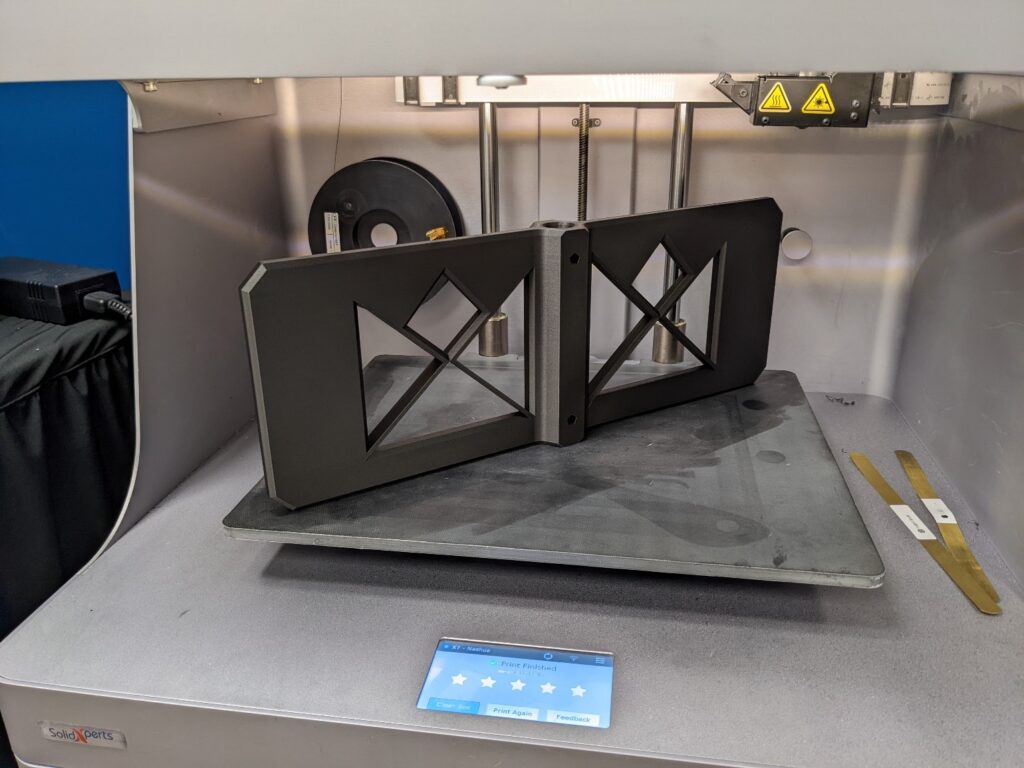

For strength Markforged Onyx filament is used which is a carbon and nylon blend. The wall passes are increased and gyroid infill is used along with maintaining the full paddle width through the paddle cross section.

Disassembly of the original paddle from the rower was a bit involved, requiring drilling and a gear puller to get the shaft clear to accept the printed replacement.

Some additional drilling and bolting allowed the new paddle to be installed on the rower shaft.

With a slight adjustment of water volume in the tank, the 3D printed replacement paddle provides the same resistance and workout as the when the machine was new.

Water flow is different with the replacement paddle but the workout is the same. And the repair is done in time for a new year of health resolutions.

John Nolin

Senior Applications Engineer

SolidXperts

if you want to know more about this subject, you can book Contact Us:

BLOG