Description

$63,751,150,423.00

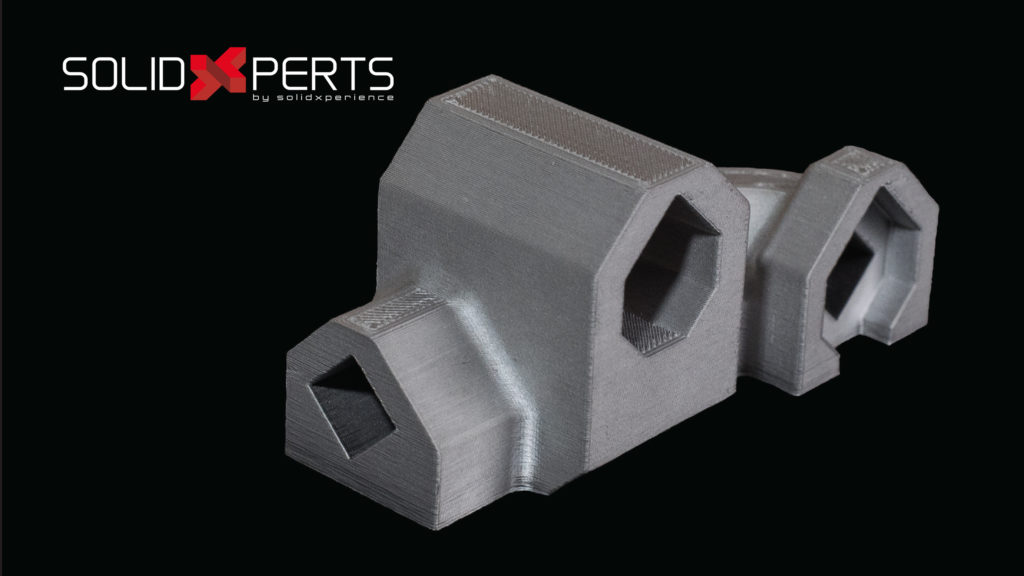

Professional accurate 3D scanning made it affordable and accessible to budget-conscious businesses.

Category: Scanner

Description

Eva Lite

Starting at:

9800

*

Professional accurate 3D scanning made it affordable and accessible to budget-conscious businesses.

What features do you get with Eva Lite?

- As a simplified version of the best-selling white light Artec Eva 3D scanner, the Artec Eva Lite features the same accuracy specifications but with geometry-only tracking and capture. Create high-quality, textureless 3D scans when working with geometrically rich objects, such as the human body. The Eva Lite is an attractive and inexpensive option for healthcare clinics with a limited budget.

- Collecting data without capturing color means that the EVA Lite is significantly less power-hungry than the original EVA scanner. It can be combined with more affordable computers, see details on recommended makes and models in our support center or contact our support team for individual inquiries.

- Eva Lite can be upgraded to Eva at any point for the price difference between the two scanners. So, if your budget allows it at a later point, you can easily get full functionality from your 3D scanner investment.

- For schools and universities, providing students with high-tech professional equipment has now become even more affordable. As part of the Artec Educational Package, the price for Eva Lite is even more accessible and also includes 20 licenses of Artec Studio, two years free upgrade, and a two-year guarantee.

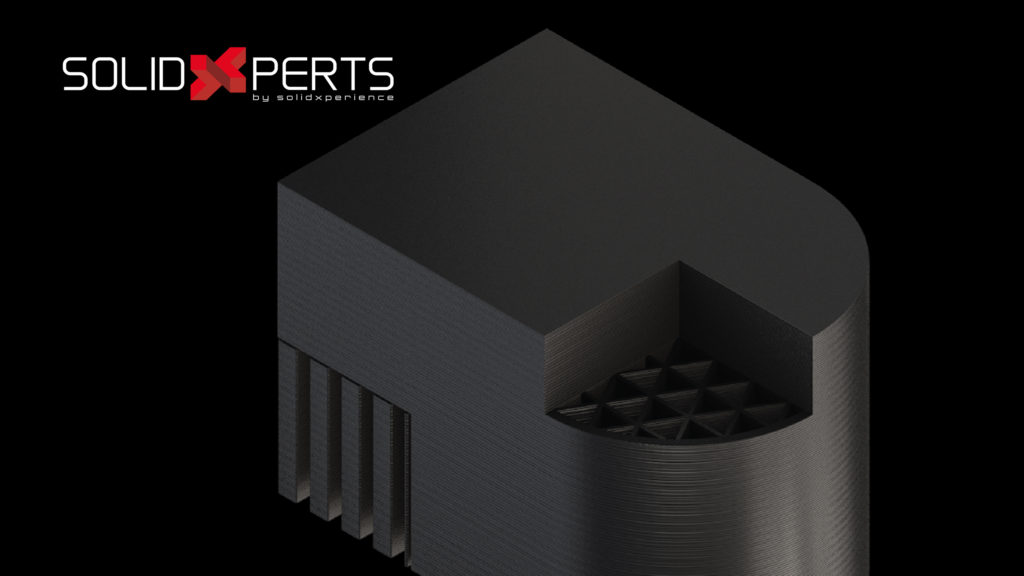

TECHNICAL SPECIFICATIONS

3D POINT ACCURACY

0.1 mm

HD MODE

No

DATA PROCESSING ALGORITHMS

Geometry based

WORKING DISTANCE

0.4 to 1 m

LINEAR FIELD OF VIEW (CLOSEST RANGE)

214 x 148 mm

LINEAR FIELD OF VIEW (FURTHEST RANGE)

536 x 371 mm

3D RECONSTRUCTION RATE

16 fps

DATA ACQUISITION SPEED

2 mln points/s

MINIMAL COMPUTER REQUIREMENTS

Intel Core i7 or i9, 32 GB RAM, GPU with 2 GB VRAM

Additional resources

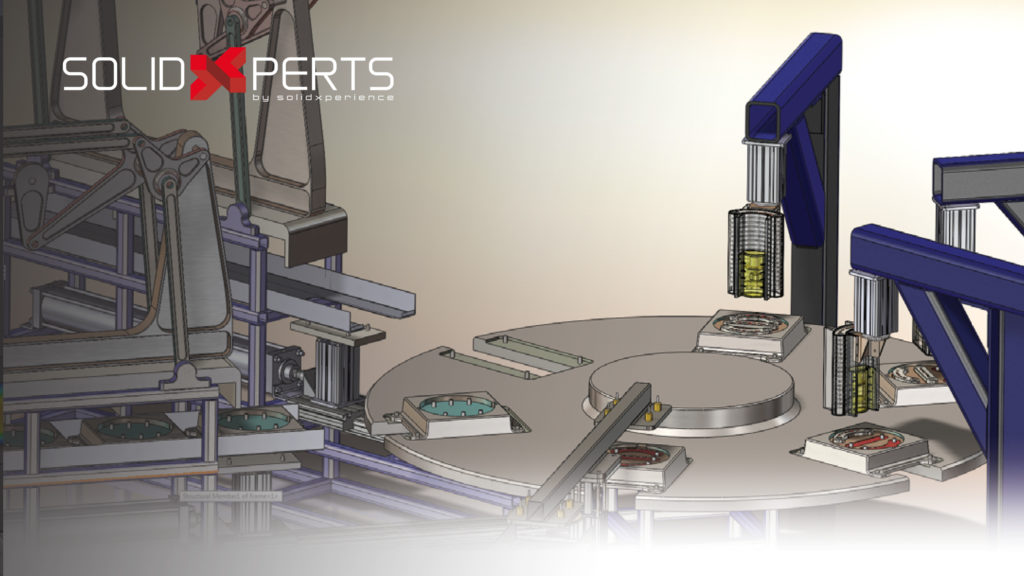

With its endless possibilities, our Xperts are here to help you find the right combination of solutions that will enhance your product by allowing you to innovate, develop, and design without limits.

Customer stories

The know-how of the SolidXperience optimization service has enabled LDV to achieve its productivity objectives, carry out large-scale projects and remain competitive against the competition.

Vincent Alie Design Director

Since implementing PDM, we have the foundation in place that we need to automate our processes, eliminate waste, and remove unnecessary costs.

Chip MontgomeryTeam Leader

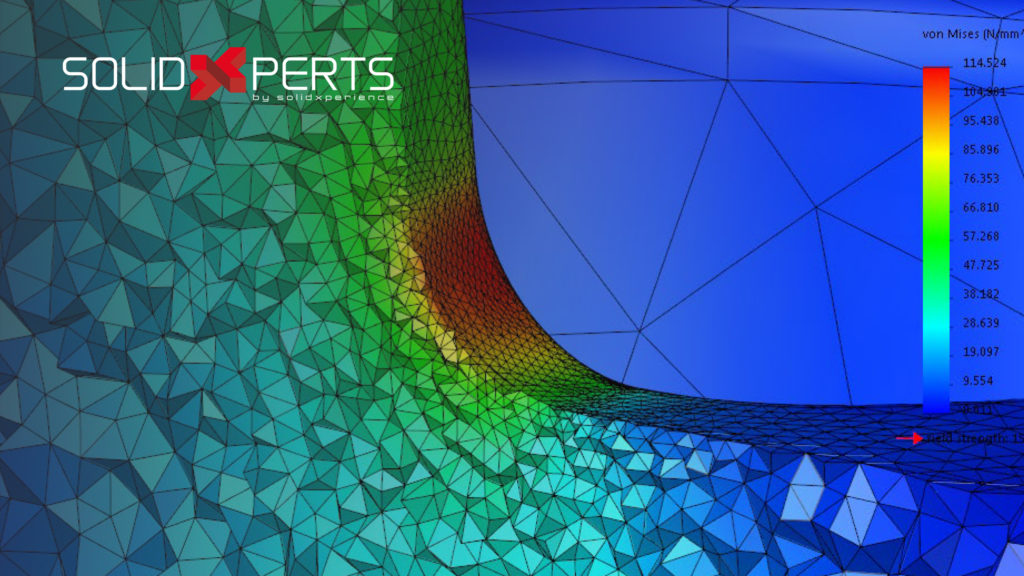

Our success rate is so high because we’ve validated close correlation between the results we get from SOLIDWORKS Plastics Professional and actual production, using photoelastic and microscopic analysis tools to confirm the software’s simulation results.

Jeffrey NicollPresident

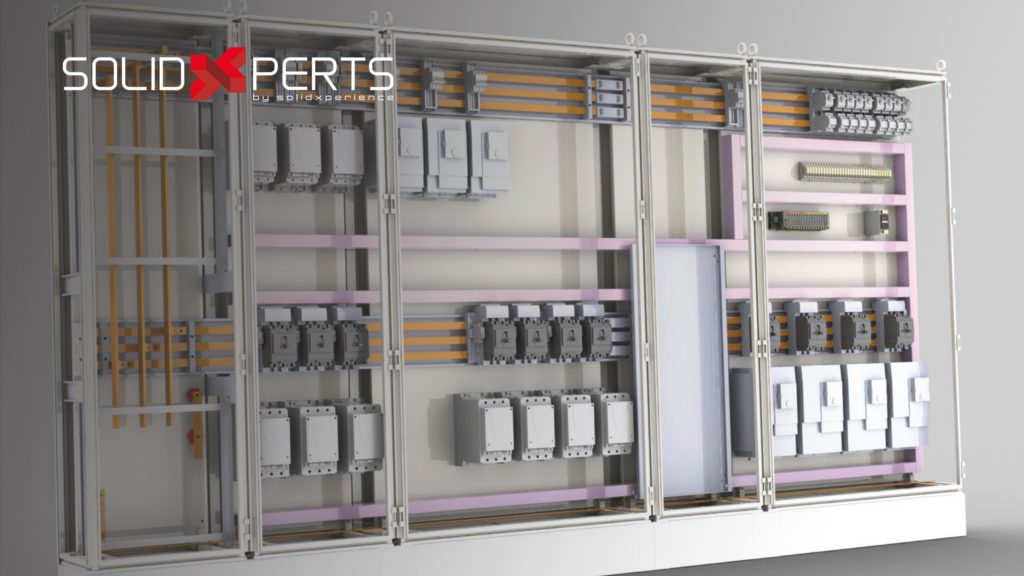

With SOLIDWORKS Electrical 3D, we’ve reduced BOM generation time from hours to minutes, and the BOM information that we output is more accurate.

Shawn EckhardtControls Engineer

From incoming part lots to in-process assembly inspections, SOLIDWORKS Inspection software helps us catch more unacceptable parts and eliminate assembly issues.

Mark GerhartConfiguration Manage

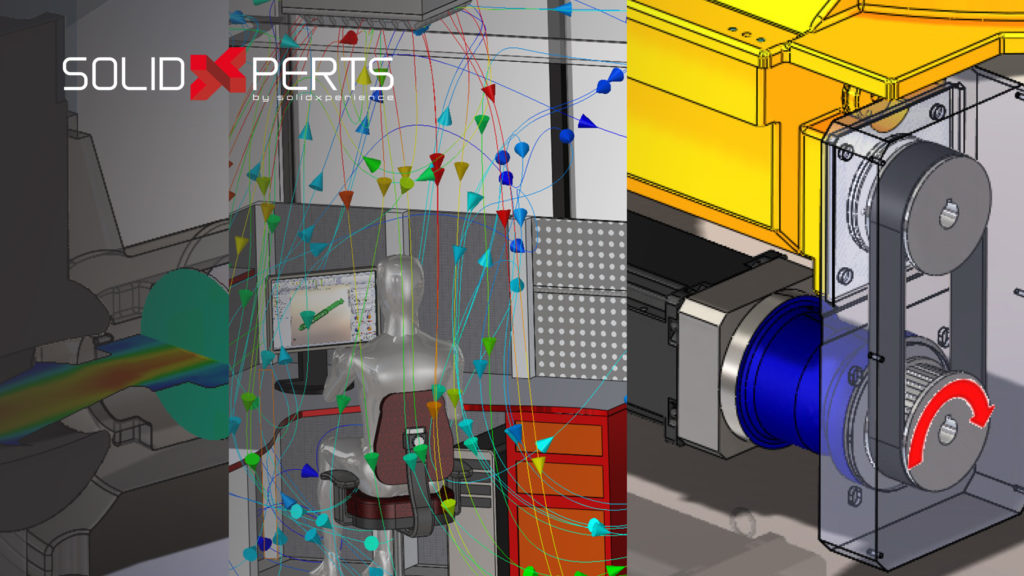

With the automation that we’ve achieved integrating SOLIDWORKS with our ERP system, our designers only have to worry about working on the design and getting that job done properly... It’s much easier to visualize and model these designs in SOLIDWORKS, and we’ve been able to automate fabrication by employing MBD techniques.

Anderson ViecelliOwner and Engineering Manager

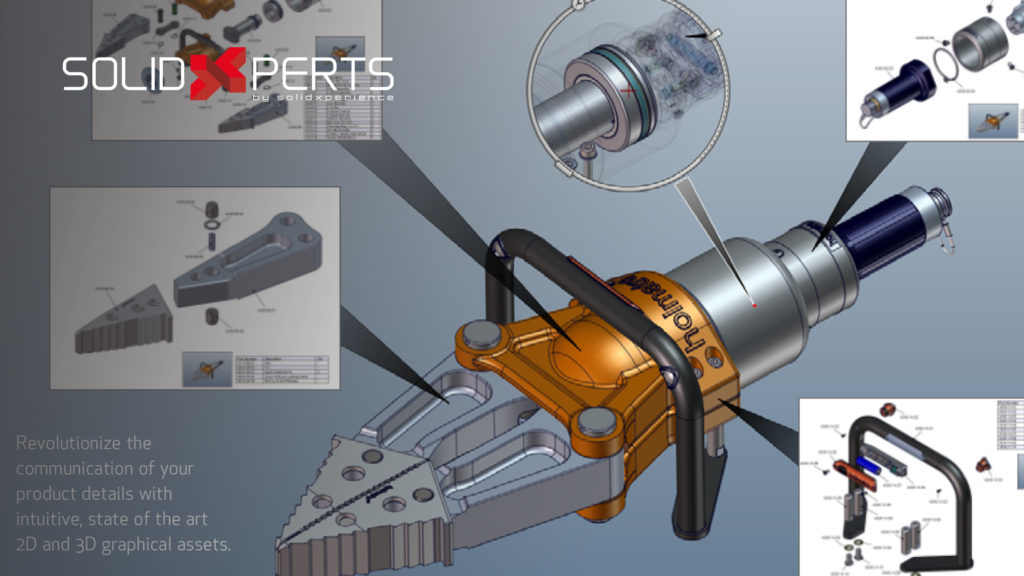

SOLIDWORKS Composer software gives us the capability to automate the creation of renderings and exploded views, which further enhances our understanding of the project.

Gary HagerSenior Project Manager/Engineer

What really sold me on SOLIDWORKS Visualize software was the ‘glass’ quality—how real it makes glass bottles look. We do a lot with glass and plastics, and we need a tool that provides the most photorealistic images possible. With the other packages, the glass quality was really not there, so we chose to standardize on SOLIDWORKS Visualize.

Jenny DeMarco StaabSenior Industrial Engineer

Ready to

unlock your potential?

Please fill the form and we will contact you soon!

Additional information

| Brand | Artec |

|---|